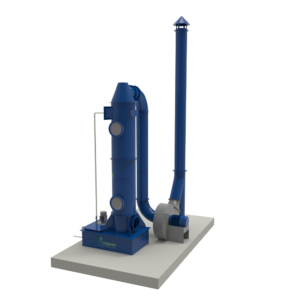

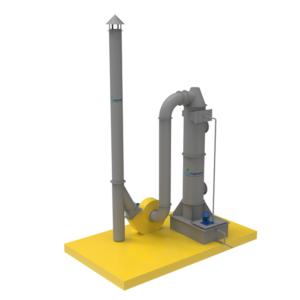

Portable Wet Scrubber

Napcen has designed and developed a portable wet scrubber for handling low volumes of acid/alkali fumes. Napcen is identified as one of the leading manufacturers of portable wet scrubbers in India. The company offers highly efficient and top-quality scrubber systems tailored to meet specific requirements. Additionally, the scrubber system can be used indoors without the need for any ducting.

Product Description

The contaminated gas stream is directed into the portable wet scrubber and is pushed downwards through an inner packed bed column. Packed-bed scrubbers feature a chamber with layers of variously shaped packing materials, such as Pall rings, Raschig rings, or Berl saddles, which offer a large surface area for liquid-gas interaction. The packing is secured by wire mesh retainers and supported by a plate at the bottom of the scrubber. The scrubbing liquid is evenly distributed above the packing and flows down through the bed, coating the packing and forming a thin film. The pollutant to be absorbed must be soluble in the fluid.

In a vertical packed bed scrubber, the gas stream moves upwards through the chamber (in opposition to the liquid flow). The clean, moist gas stream is drawn up through the unit by an internally installed blower, passes through a stainless steel mist eliminator to remove moisture from the purified air, and is then discharged from the scrubber. Any byproducts that have settled at the bottom of the water reservoir are eliminated through a drain valve.

Effectiveness Of Portable Wet scrubber:-

The effectiveness of the scrubbing solution in removing harmful gases is dependent on the concentration of the scrubbing chemical, which is continuously depleted during the process. It is crucial to maintain the scrubbing chemical concentration to ensure the scrubber’s effectiveness. Control of the scrubbing solution strength can be achieved through two methods:

1. Continuous Scrubbing: This method involves continuous replenishment and blowdown of the scrubbing solution. The composition of the scrubber solution at any given time will vary based on how it is controlled, the scrubbing chemical used, and the gases being scrubbed.

2. Batch Scrubbing: In this method, the process begins with an initially high concentration of scrubbing chemical that is allowed to deplete near exhaustion. This is followed by blowdown and replenishment with fresh, full-strength scrubber solution.

The decision on whether to control the scrubber solution strength using pH or conductivity will depend on the composition of the scrubbing solution and how it evolves during scrubber operation. While each application should be assessed individually, pH and conductivity are typically best suited for the following applications.

pH control is a common method for scrubbers utilizing continuous blowdown and replenishment. In the case of acidic gas scrubbing, such as hydrochloric acid (HCl), control is achieved by maintaining an excess concentration of a basic scrubbing chemical, such as caustic (NaOH) or lime (Ca(OH)2). The pH value is directly related to the concentration of hydrogen ions (H+), which in turn is influenced by the concentration of the basic scrubbing chemical. This relationship allows pH to effectively regulate scrubbing with minimal interference from scrubber by-products. Unlike conductivity, which is nonspecific and susceptible to by-product influence, pH control offers a more targeted approach. It is important to note that if a scrubber employs a strong caustic solution (10-15% NaOH), pH control is not recommended due to the potential damage to the pH glass electrode caused by exposure to high concentrations of caustic, leading to electrode destruction.