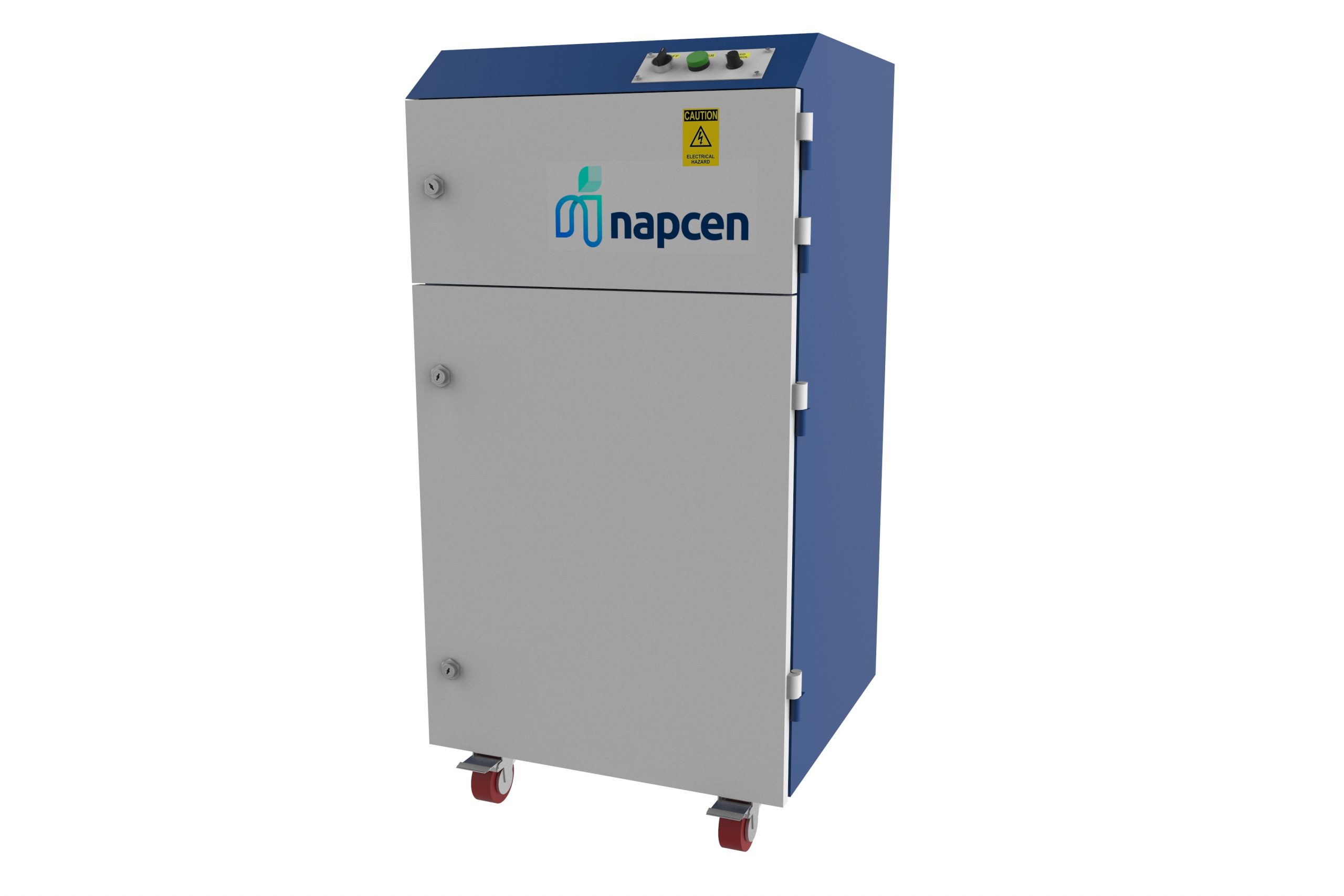

Centralized Welding Fume Extractor

Napcen Welding Fume Extractor line of Products are designed to capture hazardous fumes generated while Welding. All our Portable Welding Fume Extractors are designed with heavy-duty industry grade casters and self-supportive source capture flexible arms with hoods to give the operator full flexibility in placing the unit in relation to their welding process. All our fume extraction system are equipped with high efficient filtration media which allows a recalculating air pattern that does not require exterior ducting or make-up air.

Product Description

Napcen manufacturers welding smoke extractors, which are custom designed to meet the need of customers. Welding fume extractors are employed in extracting the welding smokes and fumes from variety of welding applications such as MIG welding, TIG welding, stick welding, cleanroom welding , production welding, stainless steel tank welding etc. Napcen welding smoke eaters are designed in such a way that they can be easily customized for example, Portable welding fume extractors can be easily moved around the work location.

Additional Information

| Air Flow | 1300 m³ / h |

|---|---|

| Filter type | Polyester bag |

| Number Of Filters | 40 |

| Power | 2.2 kW (3 HP) |

| Power Supply Voltage | 2.2 kW (3 HP), 415 V / 50 Hz / 3 Phase |

Models and Options

MODEL 1

- Welding, Grinding & Deburring Kit

- 200 FPM

- Motor: 1.0 HP / 120/1/60Hz

- Filter Type: Metal Mesh

- Product Number: DD-MINI-010P1-WGD

WGD – METAL MESH MODEL 2

- Welding, Grinding & Deburring Kit

- 250 FPM

- Motor: 1.0 HP / 120/1/60Hz

- Filter Type: Metal Mesh

- Product Number: DD-MINI-010P1-WGD

WGD – METAL MESH FILTER

- Welding, Grinding & Deburring Kit

- 300 FPM

- Motor: 1.0 HP / 120/1/60Hz

- Filter Type: Metal Mesh

- Product Number: DD-MINI-010P1-WGD

Applications

Centrifugal Blower,

Spiral Ducts,

Flexible duct,

Suction hoods,

Pre Filter,

Fine Filter,

HEPA Filter,

Carbon Filter

Accessories

- Laser Marking

- Shielded Metal Arc Welding (SMAW,stick welding)

- Gas Metal Arc Welding (GMAW) or metal inert gas (MIG Welding)

- Flux Core Arc Welding (FCAW)

- Gas Tungsten Arc Welding (GTAW) or tungsten inert gas (TIG) welding

- Submerged Arc Welding (SAW)